■System overview

PCYS-02 tank zone monitoring management system is our company designed to achieve a new generation tank zone monitoring management system for achieving a unified automatic management of tank areas and field equipment safety automation control. The system mainly completes tank zone daily production operations, security, operation management, scientific production scheduling functions.

Luɔ̈ɔ̈i de tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ Ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ Tank zone monitoring and management system application, has greatly improved the storage area, tank area automation management and operational capability, removing and reducing unnecessary intermediate links, strengthening internal management, enhancing overall operational efficiency, thereby achieving a whole system operation economical, reasonable and efficient. Tank zone monitoring and management system application, has greatly improved the storage area, tank area automation management and operational capability, removing and reducing unnecessary intermediate links, strengthening internal management, enhancing overall operational efficiency, thereby achieving a whole system operation

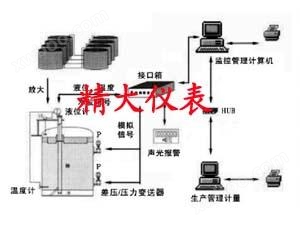

■ Sistɛm ye looi (cït mɛn ye nyuɔɔth piny)

PCYS-02 tank zone monitoring management system is mainly composed of high performance, high reliability industrial control computer (IPC), data acquisition control unit (ADAM or PLC) and various field instruments organically combined to achieve various segments of signals sharing and coordination work, completing integrated control and management functions. PCYS-02 tank zone monitoring management system is mainly composed of high performance, high reliability industrial control computer (IPC), data acquisition control unit (ADAM or PLC) and various field instruments organically combined to achieve various segments of signals sharing and coordination work, completing integrated control and management functions. Sisitɛm ye kɛ̈ɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r ye kɛ̈r

■ System function (software structure cït tɛ̈n ye nyuɔɔth piny)

1.Processing gathering and processing: It can measure a real time tank's liquid level, interface, temperature, density, volume, weight and the site combustible gas concentration, valve pump status and other parameters. 1.Processing gathering and processing: It can measure a real time tank's liquid level, interface, temperature, density, volume, weight and the site combustible gas concentration, valve pump status and other parameters. A ye tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈n yena tɛ̈

2.Display and alarm function: Display dynamically, showing each storage tank liquid level, water level bar chart. 2.Display and alarm function: Display dynamically, showing each storage tank liquid level, water level bar chart. 2.Display and alarm function: Display dynamically, showing each storage tank liquid level, water level bar chart. Na cï tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë t

3. Database management function: Database ye software ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac ye kɔc mac Ka tɛ̈n yenë wɛ̈t cï gɔ̈t në kɔc cï gɔ̈t në kɔc cï gɔ̈t në kɔc cï gɔ̈t në kɔc cï gɔ̈t në kɔc cï gɔ̈t në kɔc cï gɔ̈t në kɔc cï gɔ̈t në k

4.Report Printing Function: Luɔ̈ɔ̈i wɛ̈t ye kɔc wɛ̈t ye kɔc wɛ̈t ye kɔc wɛ̈t ye kɔc wɛ̈t ye kɔc wɛ̈t ye kɔc wɛ̈t ye kɔc wɛ̈t ye kɔc wɛ̈t

5.Operation protection function: mainly prevent non-authorized personnel operating monitoring system, the system has an alarm alert for incorrect operation, while having a password protection function when performing important operations.

6. Online parameter adjustment function: System can easily and conveniently authorize online modification of various monitoring points such as measurement range, upper and lower limits, units, and migration volumes. 6. Online parameter adjustment function: System can easily and conveniently authorize online modification of various monitoring points such as measurement range, upper and lower limits, units, and migration volumes.

7.PID ye luɔɔi: PID ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi ye luɔɔi.

8.Network Communication Function: System can use two standard configured PC computers as a detection management computer, one placed in the field monitoring room, another placed in the business management room, two computers separately connected through local area network, so that management decision makers can understand at any time, manage the storage tank operation and production.