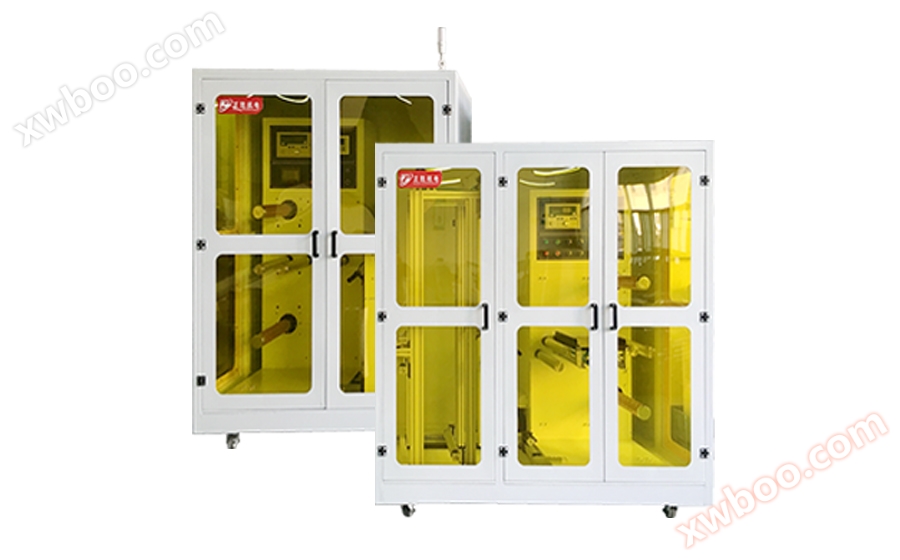

A.Equipment overview

Multifunction feeder machine ye luɔ̈ɔ̈i në roll-to-roll process, automatic roll-to-roll feeding to downstream equipment for processing,Automatic forward paragraphKä juëc ye kek tɔ̈ɔ̈u në masin ye kek tɔ̈ɔ̈u në rot ye kek tɔ̈ɔ̈u në rot ye kek tɔ̈ɔ̈u në rot ye kek tɔ̈ɔ̈u.

II.Masin laarSpecifications ku Technical Indicators

1.Applicable width: Material width 400mm, single column drop.

2.Size of Material Applicable: Diameter of Material ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni400mm, Kä ye looi 3 inch(Luɔ̈ɔ̈i kɛ gas)

3.Thickness ye looi: 0.05 ~ 0.1mm

4. Lɔ̈ɔ̈i: 400mm

5.Standart Kualitas Produk:No draw injury after dropping (No draw injury after dropping) (No draw injury after dropping) (No draw injury after dropping) (No draw injury after dropping) (No draw injury after dropping) (No draw injury after dropping) (No draw injury after dropping),Fold,Scratch & Defined Angle.

◆Funksiɔn Equipment

1.Axle ye looi: 2 3 inch gas accounting shaft.

2.Loading Method: Gas accounting shaft ye tɔ̈u në kë ye cɔl suspension mounting design, ku kä ye kek tääu thïn aye kek tääu thïn në kë ye kek tääu thïn në kë ye kek tääu thïn.

3.Metod Fixed: Gas accounting shaft uses a rotating connector, with an electromagnetic valve automatic blowing to fix the material. Gas accounting shaft uses a rotating connector, with an electromagnetic valve automatic blowing to fix the material.

4.Material torque: 1 set of automatic tension controller, with a tension detection roller,Automatic BrakeLaŋ

Axis torque, ka tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ.

5.Method ye mat: Equipped with coupling platform 1 set, platform uses vacuum adsorption to flatly adsorb materials toPingHa tɛɛr, ha tɛɛr

Pneumatic clamp ye kɔc tɔ̈ɔ̈u në kë de kä ye kek tɔ̈ɔ̈u në kë de kä ye kek tɔ̈ɔ̈u në kë de kä ye kek tɔ̈ɔ̈u,Kɛ̈ɛ̈k ye tɔ̈u në tɛ̈n ye tɔ̈u në tɛ̈n ye tɔ̈u në tɛ̈n ye tɔ̈u në tɛ̈n

Lɔ̈k.

6.Lɔ̈k cache: 1 set de buffer de looi, të cenë kä ye looi ya tɔ̈ɔ̈u,End & Next VolumeHeader yeKɔmpi

Lɔ̈ɔ̈i në tök, ka tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛKɔnɔ, ka tɛmɛ kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl

Stop.

7. Material detection: gas accounting shaft material detection * 2 group, detecting material outer diameter, less than fixed outer diameter, when the material outer diameter is less than fixed outer diameter, the material outer diameter is less than fixed outer diameter, the material outer diameter is less than fixed outer diameter, the material outer diameter is less than fixed outer diameter, the material outerPolis ye jam,

Tips to prepare the next roll of materials for joining. Lëk bï yïn kä ye kek looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi.Fitting Table Material Testing*1 grup,Na cï bɛ̈n yök lɔn, pneumatic clamp

Lɔ̈k, tɔ̈ɔ̈u kä ye kek looi, tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈uRoll tɔ̈u bɛ̈n looi.Buffer Optical Limit Check

Anem*1 grup, të cenë buffer material tɔ̈u,Ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ.

8. Lɔ̈ɔ̈i:Yïn1 set of automatic correction devices, with ultrasonic detection photoelectric. 1 set of automatic correction devices, with ultrasonic detection photoelectric. 1 set of automatic correction devices, with ultrasonic detection photoelectric. 1 set of automatic correction devices, with ultrasonic detection photoelectric.Automatic Correct

Volume,Garantiya material dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r.

9.Machine structure: whole machine bone plus using steel plate processing after welding high temperature spraying treatment, other zero. Machine structure: whole machine bone plus using steel plate processing after welding high temperature spraying treatment, other zero. Machine structure: whole machine bone plus using steel plate processing after welding high temperature spraying treatment, other zero.IronLuɔiChromium ye

Luɔi aluminium ye looi anode hardened black treatment, four round sealing plate shaft is installedSealLuɔi.

A tãŋuan,BufferSpecifications ku Technical Indicators

1.Add a buffer in the middle section of the etching line to prevent the material from running too long and pulling gentlemanRole ye.

2. Wɛ̈ɛ̈r ye looi: Wɛ̈ɛ̈r ye looi 400mm.

3. Drive mode: adopting two sets of pulling rollers, front roller back self pull, pulling material forward,Back Roller Self

Ka tɛmɛ tension, ka tɛmɛ kä ye kek looi ka tɛmɛ tension.

4.Kä ye kek looi:0.05 ~ 0.1mm yic: 1000mm

5..Product quality standard: no pull, wrinkle, scratch and defective angle phenomenon after charging,Kä ye gɔ̈ɔ̈r ye gɔ̈ɔ̈r ye gɔ̈ɔ̈r ye gɔ̈ɔ̈r ye gɔ̈ɔ̈r ye gɔ̈ɔ̈r.

6. Machine Table Structure: whole machine bone plus using steel plate processing after welding high temperature spraying treatment, other partsIron MiningPlating

Chromium treatment aluminium parts using anode hardened black treatment, four-round sealing plate axes are installing sealing treatment. Chromium treatment aluminium parts using anode hardened black treatment, four-round sealing plate axes are installing sealing treatment.Ye.

Masin dɔSpecifications ku Technical Indicators

1. Wɛ̈ɛ̈r ye looi: Wɛ̈ɛ̈r ye looi 400mm.

2.Applicable Material Size: Material large outer diameter 400mm, material inner diameter 3 inches (with gas accounting shaft use) 2.Applicable Material Size: Material large outer diameter 400mm, material inner diameter 3 inches (with gas accounting shaft use)

3.Thickness ye looi: 0.05 ~ 0.1mm

4. Lɔ̈ɔ̈i: 1000mm

5.Product quality standard: no pull, wrinkle, scratch and defective angle phenomenon after charging, coil end face neatly. 5.Product quality standard: no pull, wrinkle, scratch and defective angle phenomenon after charging, coil end face neatly.

◆Kuen-kuɛn-kuɛn

1.Charge axis: 2 3 inch gas accounting shaft.

2.Loading Method: Gas accounting shaft adopts a suspended mounting design, material is loaded from directly ahead. Gas accounting shaft adopts a suspended mounting design, material is loaded from directly ahead. Gas accounting shaft adopts a suspended mounting design, material is loaded from directly ahead.

3.Metod Fixed: Gas accounting shaft uses a rotating connector, with an electromagnetic valve automatic blowing to fix the material. Gas accounting shaft uses a rotating connector, with an electromagnetic valve automatic blowing to fix the material.

4.Load torque: Equipped with 1 set of automatic tension controller, with a tension detection roller, automatic adjusting magneticPowderCombinator

Reeling torque mat reeling motor reeling, ka tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ.

5. TakimEPC: 1 set of automatic correction devices, with ultrasonic detection photoelectric for automatic (EPC: 1 set of automatic correction devices, with ultrasonic detection photoelectric for automatic)CorrectA yic,

Kä ye kek looi aye kek looi në ±1mm.

Testing Material: Gas accounting shaft material detection * 2 group, detecting material outer diameter, larger than fixed outer diameter when: gas accounting shaft material detection * 2 group, detecting material outer diameter, larger than fixed outer diameter when: gas accounting shaft material detection * 2 group, detecting material outer diameter, larger than fixed outer diameterBeepPolis, tɔm

Switch reel ye nyuɔɔth.

Lɔ̈ɔ̈i: Lɔ̈ɔ̈i de kɔc cï lɔ̈ɔ̈i de kɔc cï lɔ̈ɔ̈i de kɔc cï lɔ̈ɔ̈i de kɔc cï lɔ̈ɔ̈iSetupLät karen

Bɛ̈n.

Machine structure: whole machine bone plus using steel plate processing after welding high temperature spraying treatment. Machine structure: whole machine bone plus using steel plate processing after welding high temperature spraying treatment. Machine structure: whole machine bone plus using steel plate processing after welding high temperature spraying treatment.Kä kɔ̈k ye kɔ̈k ye kɔ̈k ye kɔ̈k ye kɔ̈k ye kɔ̈k ye kɔ̈k ye kɔ̈k ye kɔ̈k ye kɔ̈k

Luɔi aluminium ye looi anode hardened black treatment,Four round sealing plate axes are installing sealing treatment. A ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ