Jilin Amino Acid Liquid Fertilizer Production Equipment Jilin Amino Acid Liquid Water Soluble Fertilizer Production Equipment

Jilin Amino Acid Liquid Fertilizer Production Equipment (Jilin Amino Acid Liquid Fertilizer Production Equipment)Karakteristika Produk

1. Liquid original ye filter yic, ye kä ye kek tɔ̈ɔ̈u nyaai.

2. Automatic ingredient system, bɛ kɛ̈ɛ̈r wɛɛr

3. Reactor reactor reaction, ye kä juëc ye kek looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi looi. Lɔ̈k bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n looi.

4. Lɔ̈ɔ̈m ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc

5. Lɔ̈ɔ̈m ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u.

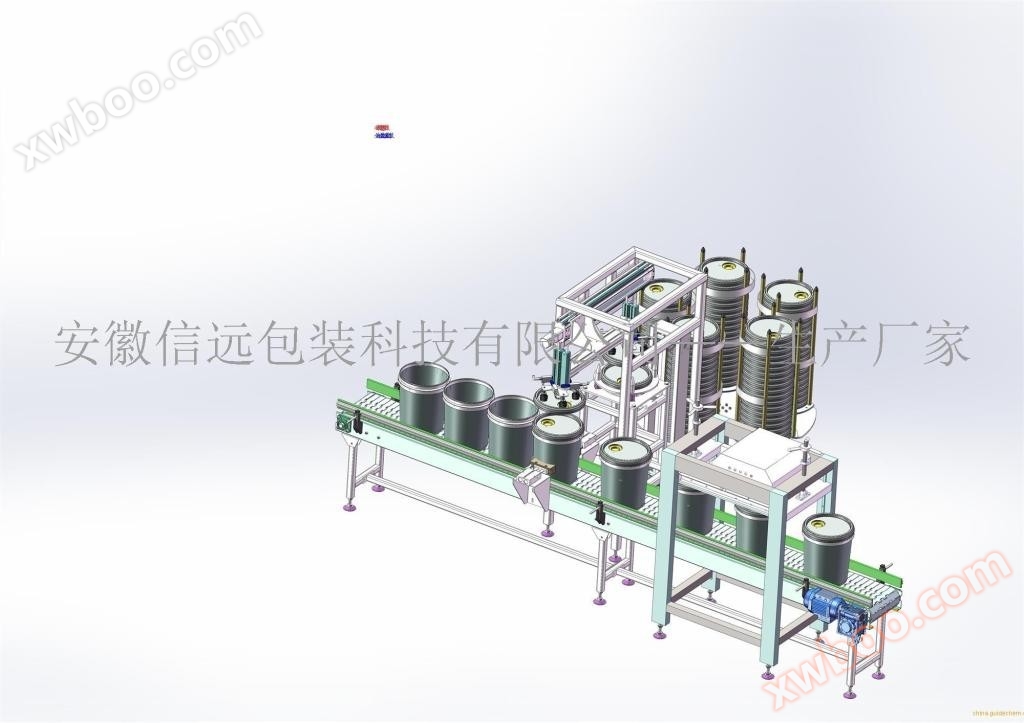

6.Filling tɔ̈u në baril dït filling ku bottle dït filling production line.

7. Automatic packing line

8. Automatic palletizing line

Jilin Amino Acid Liquid Water Soluble Fertilizer Production Equipment (Jilin Amino Acid Liquid Water Soluble Fertilizer Production Equipment)Proses:

Barrel filling line: poly bottle <unk> filling --- rotating cap --- label --- sealing jet --- out of box --- packaging --- palletizing

Bagging filling line: filling--packing--finished product conveyor

Layout de luɔɔi:

2nd floor: (Bao Village tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u tɔ̈ɔ̈u

1st floor (1 main packing floor, Ray a man is responsible for all floor equipment operation maintenance) (1 main packing floor, Ray a man is responsible for all floor equipment operation maintenance) (1 main packing floor, Ray a man is responsible for all floor equipment operation maintenance) (1 main packing floor, Ray a man is responsible for all floor equipment operation maintenance) (1 main packing floor

(2 palletisation de kä cï looi ku kä cï looi në tɛ̈n yenë kek ya tɔ̈ɔ̈u thïn, raan ye luui tök wïc bï kek ya tɔ̈ɔ̈u në palletisation de kä cï looi)

Production Line Equipment Composition:

2nd floor: Fully automatic box opening machine drop box machine, Shangyang platform, upper cover platform

1st floor: Fully automatic bottle machine Fully automatic filling machine Fully automatic spinning cap machine Aluminum bar sealing machine

Positioning labeling machine, packaging machine full automatic box sealing machine full automatic robot palletizing machine, general control electrical cabinet.

Features of baara:

1, tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n

2, Integrated, Smart Packaging

3, kɔc ye luɔɔi looi ku kɔc ye luɔɔi looi

4, luɔɔi ye yic, kä ye kek tääu thïn ye kek tɔ̈ɔ̈u ye kek tɔ̈ɔ̈u ye kek tɔ̈ɔ̈u ye kek tɔ̈ɔ̈u

5, tɛ̈n yenë yen luɔ̈ɔ̈i thïn

Anhui Xin acï kä juëc ye kek looi në ruöön de 2013 bɛ̈n ya looi në luɔɔi de kä ye kek looi në luɔɔi de kä ye kek looi në luɔɔi de kä ye kek looi në luɔɔi de kä ye kek looi në luɔɔi de kä ye kek looi në luɔɔi de kä ye kek looi Në ruöön de 2014, Xinyuan acï bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n looi bɛ̈n loo

A tɔŋa microbial fermentation process, a tila 5 processes. 1 Lɔ̈ɔ̈m ye tɔ̈ɔ̈u, lɔ̈ɔ̈m ye tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u 2, vaccination fermentation, marsh liquor in the fermentation tank, vaccination specific beneficial organisms, and accompanied by a sufficient mixing mix, the liquid remains in the fermentation tank after being delivered to the ingredient tank. 2, vaccination fermentation, marsh liquor in the fermentation tank, vaccination specific beneficial organisms, and accompanied by a sufficient mixing mix, the liquid remains in the fermentation 3, kä ye kek looi, ago kä ye kek looi ya cɔk tɔ̈ɔ̈u në bɛ̈ɛ̈i yiic yiic, a wïc ba kä ye kek looi ya cɔk tɔ̈ɔ̈u në bɛ̈ɛ̈i yiic yiic yiic yiic yiic yi 4, tɔ̈ɔ̈u, tɔ̈ɔ̈u, tɔ̈ɔ̈u, tɔ̈ɔ̈u, tɔ̈ɔ̈u, tɔ̈ɔ̈u, tɔ̈ɔ̈u, tɔ̈ɔ̈u, tɔ̈ɔ̈u 5, packing, ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ.

Workflow

Raw materials<unk>Reactor<unk>Conveyor pump<unk>Dual filter/grinding<unk>Storage tank<unk>Conveyor pump<unk>Filling machine<unk>Press cover/rotating cover<unk>Conveyor

Karakteristika baara

1, PLC automation process control, according to the prescriptions formula automatic distribution ratio, greatly saving labor costs and labor ingredients error caused waste. 1, PLC automation process control, according to the prescriptions formula automatic distribution, greatly saving labor costs and labor ingredients error caused waste.

2, kä ye kek looi ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ

3、System equipment has a discharge mechanism, easy after production cleaning. 3、System equipment has a discharge mechanism, easy after production cleaning. 3、System equipment has a discharge mechanism, easy after production cleaning. 3、System equipment has a discharge mechanism, easy after production cleaning.

4. Masin kënë ye luɔɔi de 304 stainless steel ye cɔl corrosion resistant, kä ye kek looi aye kek looi de 316 stainless steel

Parameters Teknikal

1, User interface: DN65 material import pressure <0.6Mpa;

2Diameter raan cage:40 mm;

3, tɛ̈n yenë yen tɔ̈u thïn: min 140 * 200 * 320mm; * 260 * 290 * 500mm;

4, tɛ̈n yenë yen tɔ̈ɔ̈u thïn: 5-30kg;

5Tɛɛr tɛɛr:±0.2% (Note: ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ)

6, tɛ̈ɛ̈r tɔ̈u: ≤250 baril / hr (5kg);

7, kaam ye kɔnɔ: 0.6-0.7 MPa;

8, wɛ̈ɛ̈r ye kɔɔr: 120L/min;

9, Power: ~ 380 volts, 30Hz

10, Puɔth: 1.6KW

11, kɛ̈ɛ̈r: 1000kg;

12, Dimension: 8700 * 1350 * 2300mm ((Length * Width * Height)

Amino acids alkaline ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ;

Features:

Parasite ye duniŋ: ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ

Anti-salt anti-reversal: algae ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ

Loose soil preservation fertilizer: ka organic matter (organic carbon) bɛ̈n ya juak, ka bɛ̈n ya juak, ka bɛ̈n ya juak, ka bɛ̈n ya juak, ka bɛ̈n ya juak, ka bɛ̈n ya juak, ka bɛ̈n ya juak, ka bɛ̈n ya juak, ka bɛ̈n ya juak, ka bɛ̈n ya juak.

Green leaf production stable: algae carbobacterium polyase ye kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ

Nutrition full: Acid an ye wïc bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈

Root Growth Plantation: A ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ A bɛ kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈

Kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ kɔnɔ

Tɛ̈n yenë yen luɔ̈ɔ̈i thïn: ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye A lëu bï ya tɔ̈ɔ̈u kek kɔc kɔ̈k ye.