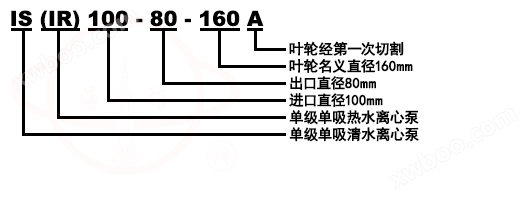

Model maana

Produk Profile

IS horizontal single stage single suction pipeline pump, ye luɔɔi në ɣän ke luɔɔi ku ɣän ke bɛ̈ɛ̈i yiic, ku ye luɔɔi në ɣän ke puɔ̈ɔ̈c ku ɣän ke puɔ̈ɔ̈c. A tɛ̈ɛ̈r ye tɔ̈ɔ̈u në 80°C ye tɛ̈ɛ̈r ye tɛ̈ɛ̈r ye tɛ̈ɛ̈r ye tɛ̈ɛ̈r ye tɛ̈ɛ̈r ye tɛ̈ɛ

Pump ye luɔɔi (në kë de design point):

Rotation speed: 2900r/min ku 1450r/min

Diameter: 50-200mm

Lɔ̈ɔ̈i: 6.3-400 m3/h

Lift: 5-125

Kuen karen

1, a lëu bï ya luui në ɣän ke gɛu, ɣän ke gɛu, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc, ɣän ke kɔc

2, a lëu bï ya luui në pii cɔl, pii yiic ku jɔl ya kɛ̈ɛ̈r ye cɔl chemical media ye cɔl acidity, alkalinity ku jɔl ya kɛ̈ɛ̈r ye cɔl paste (kɛ̈ɛ̈r ye cɔl viscosity≤100 cm per, kɛ̈ɛ̈r ye

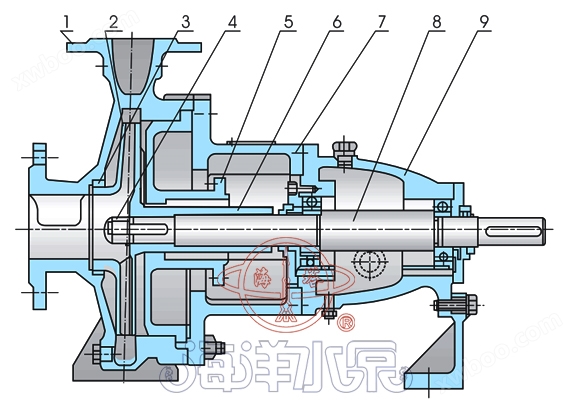

Struktur diagram

|

Serial No |

Nyuɔ |

Serial No |

Nyuɔ |

1 |

Pump body |

6 |

Middle bracket |

|

2 |

Wheel |

7 |

Axis

|

|

3 |

Sealing Ring |

8 |

Suspension Parts |

|

4 |

Wheel nut |

9 |

Kuen sealing |

|

5 |

Pump Cover |

Parametre luɔɔi

|

Model

|

Lɔɔr Q

|

Haŋ H

|

Rotational speed n

|

Motor Power

|

|

|

m3/h

|

L/s |

m |

r/min |

kW |

|

IS50-32-125 |

12.5 |

3.47 |

20 |

2900 |

2.2 |

IS50-32-160 |

12.5 |

3.47 |

32 |

2900 |

3 |

IS50-32-200 |

12.5 |

3.47 |

50 |

2900 |

5.5 |

IS50-32-250 |

12.5 |

3.47 |

80 |

2900 |

11 |

IS65-50-125 |

25 |

6.94 |

20 |

2900 |

3 |

IS65-50-160 |

25 |

6.94 |

32 |

2900 |

5.5 |

IS65-40-200 |

25 |

6.94 |

50 |

2900 |

7.5 |

IS65-40-250 |

25 |

6.94 |

80 |

2900 |

15 |

IS65-40-315 |

25 |

6.94 |

125 |

2900 |

30 |

IS80-65-125 |

50 |

13.9 |

20 |

2900 |

5.5 |

IS80-65-160 |

50 |

13.9 |

32 |

2900 |

7.5 |

IS80-50-200 |

50 |

13.9 |

50 |

2900 |

15 |

IS80-50-250 |

50 |

13.9 |

80 |

2900 |

22 |

IS80-50-315 |

50 |

13.9 |

125 |

2900 |

37 |

IS100-80-125 |

100 |

27.8 |

20 |

2900 |

11 |

IS100-80-160 |

100 |

27.8 |

32 |

2900 |

15 |

IS100-65-200 |

100 |

27.8 |

50 |

2900 |

22 |

IS100-65-250 |

100 |

27.8 |

80 |

2900 |

37 |

IS100-65-315 |

100 |

27.8 |

125 |

2900 |

75 |

IS125-100-200 |

200 |

55.5 |

50 |

2900 |

45 |

IS125-100-250 |

200 |

55.6 |

80 |

2900 |

75 |

IS125-100-315 |

200 |

55.6 |

125 |

2900 |

90 |

Model |

Lɔɔr Q |

Haŋ H |

Rotational speed n |

Motor Power |

|

m3/h |

L/s |

m |

r/min |

kW |

|

IS50-32-125 |

6.3 |

1.74 |

5 |

1450 |

0.55 |

IS50-32-160 |

6.3 |

1.74 |

8 |

1450 |

0.55 |

IS50-32-200 |

6.3 |

1.74 |

12.5 |

1450 |

0.75 |

IS50-32-250 |

6.3 |

1.74 |

20 |

1450 |

1.5 |

IS65-50-125 |

12.5 |

3.74 |

5 |

1450 |

0.55 |

IS65-50-160 |

12.5 |

3.47 |

8 |

1450 |

0.75 |

IS65-40-200 |

12.5 |

3.74 |

12.5 |

1450 |

1.1 |

IS65-40-250 |

12.5 |

3.74 |

20 |

1450 |

2.2 |

IS65-40-315 |

12.5 |

3.74 |

32 |

1450 |

4 |

IS80-65-125 |

25 |

6.94 |

5 |

1450 |

0.75 |

IS80-65-160 |

25 |

6.94 |

8 |

1450 |

1.5 |

IS80-50-200 |

25 |

6.94 |

12.5 |

1450 |

2.2 |

IS80-50-250 |

25 |

6.94 |

20 |

1450 |

3 |

IS80-50-315 |

25 |

6.94 |

32 |

1450 |

5.5 |

IS100-80-125 |

50 |

13.9 |

5 |

1450 |

1.5 |

IS100-80-160 |

50 |

13.9 |

8.0 |

1450 |

2.2 |

IS100-65-200 |

50 |

13.9 |

12.5 |

1450 |

4 |

IS100-65-250 |

50 |

13.9 |

20 |

1450 |

5.5 |

IS100-65-315 |

50 |

13.9 |

32 |

1450 |

11 |

IS125-100-200 |

100 |

27.8 |

12.5 |

1450 |

7.5 |

IS125-100-250 |

100 |

27.8 |

20 |

1450 |

11 |

IS125-100-315 |

100 |

27.8 |

32 |

1450 |

15 |

IS125-100-400 |

100 |

27.8 |

50 |

1450 |

30 |

IS150-125-250 |

200 |

55.6 |

20 |

1450 |

18.5 |

IS150-125-315 |

200 |

55.6 |

32 |

1450 |

30 |

IS150-125-400 |

200 |

55.6 |

50 |

1450 |

40 |

IS200-150-250 |

400 |

111.1 |

20 |

1450 |

37 |

IS200-150-315 |

400 |

111.1 |

32 |

1450 |

55 |

IS200-150-400 |

400 |

111.1 |

50 |

1450 |

90 |

Lɔ̈k kɛnɛ jɔl

IS horizontal single-stage single suction pipe pump assembly and removal pump should first check whether parts have a impact on assembly defects, and scrub clean, before it can be assembled. IS horizontal single-stage single suction pipe pump assembly and removal pump should first check whether parts have a impact on assembly defects, and scrub clean, before it can be assembled.

1, ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen.

2. A lëu ba O-shaped sealing ring, paper mat, felt, etc. tɔ̈ɔ̈u në ɣän kɔ̈k peei yiic.

3, aw bɛ se ka tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ

4, tɔ̈ɔ̈u roller bearing në axis, ku tɔ̈ɔ̈u në suspension, ku tɔ̈ɔ̈u piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny piny

5, tɔ̈ɔ̈u axis në axis, ku tɔ̈ɔ̈u pump cover në suspension, ku tɔ̈ɔ̈u wheel, stop gasket, wheel nut, ku jɔl ya tɔ̈ɔ̈u. Lɔ̈ɔ̈m ba awowa cï gɔ̈ɔ̈r dɔ̈ɔ̈r ya tɔ̈ɔ̈u pompe dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈

Në tɛ̈n yenë yen looi thïn, kä thiin koor cït mɛn ye flat key, oil block, O-shaped sealing ring ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ ye kɔnɔ.

IS horizontal single stage single suction pipe pump removal order can be done in reverse according to the assembly order. IS horizontal single stage single suction pipe pump removal order can be done in reverse according to the assembly order.

Install

IS horizontal single stage single suction pipe pump installation pump installation has a significant impact on the operation and life of the pump, so installation and correction must be done carefully. IS horizontal single stage single suction pipe pump installation pump installation has a significant impact on the operation and life of the pump, so installation and correction must be done carefully. IS horizontal single stage single suction pipe pump installation Pump's form and installation size (Pump's form and installation size)

1Installation and correction (Lɔ̈ɔ̈i ku Lɔ̈ɔ̈i):

(1) Lɔ̈ɔ̈m ye kɔnɔ̈ɔ̈ŋ ye kɔnɔ̈ɔ̈ŋ ye kɔnɔ̈ɔ̈ŋ ye kɔnɔ̈ɔ̈ŋ ye kɔnɔ̈ɔ̈ŋ ye kɔnɔ

(2) ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ

(3) Cement ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r.

(4) Ka tɛmɛ, ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ.

(5) Lɔ̈k piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny de piny

(6) A dhil tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈

Ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ, ka tɛmɛ

2Installation Instructions:

(1) Pump's installation height, length of the pipeline, diameter, and flow speed should conform to the calculation, trying to reduce unnecessary losses.

(2) When long distance transport should take large tube diameter, pump's pipeline should have its own bracket, don't allow the weight of the pipeline to be added to the pump, to avoid pressing the pump bad.

(3) Ka tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n

Start, Stop and Run (Lɛ̈k, Lɛ̈k, Lɛ̈k, Lɛ̈k)

1Start:

(1) Ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen ka tɛmɛ yen.

(2) Gɛ̈ɛ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r.

(3) Pii bɛ̈n tɔ̈ɔ̈u në pomp yic, wala pii bɛ̈n tɔ̈ɔ̈u në pomp de vacuum yic.

(4) Connect the power supply, when the pump reaches the normal rotation speed, then gradually open the throttle valve on the throttle pipe, and adjust to the desired situation, in the throttle. The throttle valve on the tube is closed, the pump continuous working time should not exceed 3 minutes. (4) Connect the power supply, when the pump reaches the normal rotation speed, then gradually open the throttle valve on the throttle pipe, and adjust to the desired situation, in the thro

2Stop:

(1) Ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ ka tɛmɛ.

(2) Ne tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ

(3) Ni a tɛ̈n tɔ̈ɔ̈u ka tɛ̈n tɔ̈ɔ̈u ka tɛ̈n tɔ̈ɔ̈u ka tɛ̈n tɔ̈ɔ̈u ka tɛ̈n tɔ̈ɔ̈u ka

3.Luɔi:

(1) Tɛ̈n yenë yen cath ku ye luui thïn, a wajib ba tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen

(2) A tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛ

(3) Kuen ye looi aye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈

(4) Lɔ̈ɔ̈i ye cɔl bearing oil adhil tɔ̈ɔ̈u në tɛ̈n yenë yen tɔ̈ɔ̈u thïn, ka lëu bï ya tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈

(5) Ni tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n

Tabel Reference Pipeline Loss

Diameter tubu mm |

Lɔ̈ɔ̈m (L/S) |

|||||||||||||||||||||||

1 |

2 |

4 |

6 |

8 |

10 |

|||||||||||||||||||

25 |

3.2 |

13 |

||||||||||||||||||||||

38 |

3.5 |

14 |

15 |

15 |

20 |

|||||||||||||||||||

50 |

0.8 |

3.1 |

13 |

29 |

25 |

30 |

||||||||||||||||||

65 |

0.8 |

3.2 |

7.1 |

13 |

20 |

40 |

50 |

|||||||||||||||||

75 |

0.4 |

1.6 |

3.3 |

5.9 |

9.6 |

21.6 |

60 |

70 |

||||||||||||||||

100 |

0.4 |

0.8 |

1.3 |

2.1 |

6.8 |

8.6 |

13 |

19. |

80 |

90 |

||||||||||||||

125 |

0.2 |

0.4 |

0.6 |

1.3 |

2.7 |

4.1 |

5.9 |

10. |

100 |

110 |

||||||||||||||

150 |

0.1 |

0.2 |

0.5 |

1.1 |

1.6 |

2.3 |

4.2 |

6.4 |

9.4 |

120 |

130 |

|||||||||||||

175 |

0.1 |

0.2 |

0.5 |

0.7 |

1.0 |

1.9 |

2.9 |

4.3 |

5.8 |

7.7 |

9.6 |

140 |

160 |

|||||||||||

200 |

0.1 |

0.2 |

0.3 |

0.5 |

0.9 |

1.5 |

2.1 |

2.9 |

3.7 |

4.7 |

6.1 |

7.2 |

8.5 |

180 |

200 |

|||||||||

250 |

0.1 |

0.1 |

0.2 |

0.3 |

0.5 |

0.7 |

0.9 |

1.2 |

1.5 |

1.9 |

2.3 |

2.8 |

3.3 |

3.7 |

4.9 |

5.2 |

||||||||

300 |

0.1 |

0.1 |

0.2 |

0.3 |

0.4 |

0.5 |

0.6 |

0.7 |

0.9 |

1.1 |

1.3 |

1.5 |

2.0 |

2.4 |

3.0 |

|||||||||

Valve & bend tube folding straight tube length

suguya |

Diyametri tubu ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r |

Kommentar |

Valve dɔ̈ŋ |

12 |

Ka't Open Double |

Standard bending tube |

25 |

|

Valve ye wal |

100 |

|

Valve ye piny |

100 |

Kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl ye kɔl |

Lɔ̈ɔ̈i dɔ̈ŋ de pip wala lɔ̈ɔ̈i dɔ̈ŋ

|

|

Lɛɛr ye kɛ̈n ye kɛ̈n ye kɛ̈n ye kɛ̈n ye kɛ̈n ye kɛ̈n ye kɛ̈n ye kɛ̈n

Failure |

Sabab |

Solution ye |

1, pomp de pii cïï pii bɛ̈n tɔ̈ɔ̈u, pressure meter ku vacuum meter ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u. |

Pii cïï bɛ̈n tɔ̈ɔ̈u në pomp de pii yic, pii cï bɛ̈n tɔ̈ɔ̈u në tub de pii yic wala ka bɛ̈n tɔ̈ɔ̈ |

Lɔ̈k ka bɛ̈n ka bɛ̈n ka bɛ̈n ka bɛ̈n ka bɛ̈n ka bɛ̈n ka bɛ̈n ka bɛ̈n ka bɛ̈n ka bɛ |

|

2, pump de pii cïï pii tɔ̈ɔ̈u, vacuum meter ye nyuɔɔth vacuum dït.

|

Valve dɔ̈ɔ̈r ka cïï lɔ̈ɔ̈m, wala a cï lɔ̈ɔ̈m ka cïï lɔ̈ɔ̈m ka cïï lɔ̈ɔ̈m ka cïï lɔ̈ɔ̈m ka cïï

|

Lɔ̈k wala waar valve de piny. Lɔ̈ɔ̈m wala lɔ̈ɔ̈m piŋ piŋ piŋ piŋ piŋ piŋ piŋ piŋ piŋ piŋ piŋ piŋ piŋ piŋ piŋ piŋ.

|

3, tïŋ tɛ̈n yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen |

Pii ye bɛ̈n dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ |

Lɔ̈k ba piyi tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈

|

4, tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n yenë yen tɛ̈n |

Pump ye kɛ̈ɛ̈r, ku kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye. |

Lɔ̈k pomp ku tubu, ku lɔ̈k kɔrɔ. |

5. Pump ye tɔ̈u në riɛl juëc. |

Filling function pressure is too tight, filling function heats, because wear wheel broke, water pump supply increased. Filling function pressure is too tight, filling function heats, because wear wheel broke, water pump supply increased. |

Lɔ̈ɔ̈m kɔnɔ, wala lɔ̈ɔ̈m kɔnɔ, lɔ̈ɔ̈m kɔnɔ, lɔ̈ɔ̈m kɔnɔ, lɔ̈ɔ̈m kɔnɔ, lɔ̈ɔ̈m kɔnɔ. |

|

6. Pump ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u

|

A tɛmɛ dɔɔni, a tɛmɛ dɔɔni, a tɛmɛ dɔɔni, a tɛmɛ dɔɔni, a tɛmɛ dɔɔni, a tɛmɛ dɔɔni, a tɛmɛ dɔɔni. |

Ka dɔ̈ɔ̈r ka dɔ̈ɔ̈r ka dɔ̈ɔ̈r ka dɔ̈ɔ̈r ka dɔ̈ɔ̈r ka dɔ̈ɔ̈r ka dɔ̈ɔ̈r ka dɔ̈ɔ̈r ka dɔ̈ɔ̈r ka dɔ̈ɔ̈ Lɔ̈ɔ̈m bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i bɛ̈ɛ̈i |

7, ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc. |

No oil, pump shaft and motor shaft are not in a central line. No oil, pump shaft and motor shaft are not in a central line. No oil, pump shaft and motor shaft are not in a central line.

|

Lɔ̈ɔ̈m, ku lɔ̈ɔ̈m axis center. |

8, Pump ye vibrate. |

Pump shaft ku motor shaft tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ

|

Lɔ̈ɔ̈m pomp ku motɛɛr ye cɛ̈ɛ̈r ye cɛ̈ɛ̈r ye cɛ̈ɛ̈r ye cɛ̈ɛ̈r ye. |